Project Overview

Dr. Feng Chen

Ionic liquid engineered all-wood materials for high-ends applications

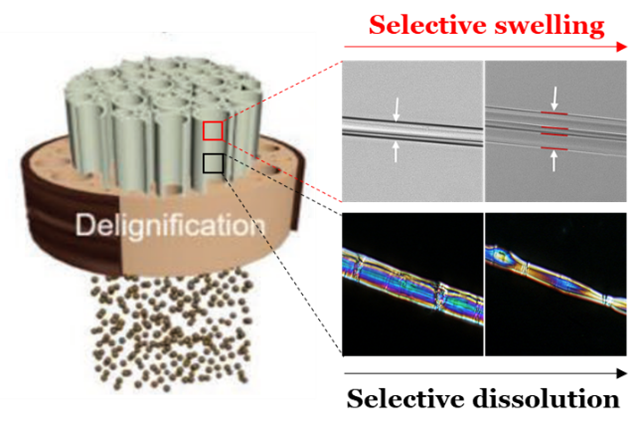

Wood as an abundant biomass is increasingly utilized to achieve renewable materials with desired properties through various nanostructure-engineered strategies. However, the interfacial strength in transverse direction and the structure stability of those wood-based materials are normally weak and rarely reported. Benefiting from the previous fundamental studies on (nano) cellulose dissolution and swelling and lignocellulose materials design experiences, Feng currently focus on further developing the concept of self-reinforced and self-“infiltrated” all-wood materials via selective dissolution and swelling strategy utilizing an ionic liquid. Moreover, this biotechnology strategy will promisingly enable desired design of stable wood structures with tunable mechanical, optical and even electrical performance for various high-ends applications.

Yong Ding

Janus wood membranes for autonomous water transport

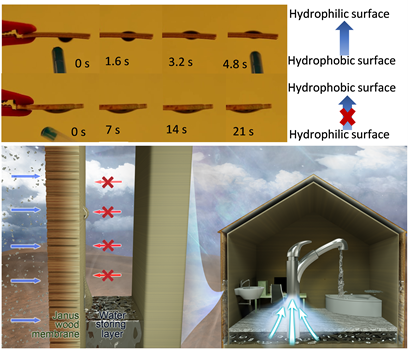

Autonomous and directional transport of liquids is crucial for many applications, such as microfluidic manipulation, chemical analysis, microreactors. Particularly, Janus membranes, with asymmetric wettability on two sides, represent enticing opportunities to address this challenge. However, elaborate bottom-up fabrication processes and poor mechanical performance of commonly employed membrane substrates often restrict their utilization, especially for engineering applications. Mechanically robust bio-based and renewable wood-based Janus membranes represent a crucial milestone towards larger-scale application of Janus membranes, for example in bilayer structures with excellent fog-capturing efficiency implemented in future smart building applications.

Christopher Dreimol

Sustainable wood-based electronics for smart buildings

Electronic waste (E-waste) is a huge concern all over the world, as one of the fastest growing waste streams in terms of both volume and environmental impact. Laser engraving graphene-like (LIG) conductive patterns on biological substrates, and especially on wood, is a promising strategy towards the development of environmentally friendly and sustainable electronics. The large-scale manufacturing of high-quality conductive patterns on wood remains challenging due to its complex surface, an inhomogeneous structure with variable chemical composition. Other factors, such as high ablation rates, the need of multiple lasing steps, and the use of fire retardants, are also limiting the applicability of conventional laser processes for the production of sustainable LIG-based electronic devices. Christopher’s aim is to develop novel approaches to laser-engraved conductive patterns on wood and wood-derived materials. Combining a fast CO2-laser treatment in normal atmosphere with a simple chemical pre-treatment of wood, he obtains highly conductive surfaces with unprecedented efficiency on large scale. He will further focus on the production of complex conductive patterns to implement built-in interfaces and environmental sensors (e.g. temperature, humidity, pressure, gases) for future smart buildings.

Alessia Ferrara

Mechanosorptive Creep Behaviour of Wood

Alessia Ferrara works on the mechanosorptive creep behaviour of wood tissues subjected to different loading conditions. The work involves a combined experimental-numerical approach. The creep experiments are conducted in a climate-controlled chamber in order to identify the parameters of constitutive models for FEM simulations.

Sophie Koch

Bio-Based Cellulose Composites

Sophie is working on sustainable composites made from cellulose and bio based polymers. She aims at preserving the structural intricacy and alignment of cellulosic fibers in wood by applying a structure-retaining delignification process. The combination of these high strength scaffolds with various polymers, ranging from hydrogels to thermosetting resins, give rise to a versatile composite design strategy. With her academic background in wood technology and bio-based materials, Sophie’s research focuses on tunable mechanical properties introduced by structural and chemical changes of the matrix polymers.

Jonas Maas

Hygro-mechanical creep behaviour of cellulose materials on a macroscopic scale

Jonas Maas works on the topic of mechanosorptive creep of hardwood on a macroscopic scale. His work includes the simulation of wooden creep behaviour via FEM, experiments for the determination of mechanosorptive properties and the modeling of wood-adhesive interactions. The experiments are conducted in climate-controlled environments and are the basis for rheological material models.

Dr. Hajar Razi

Toughening mechanisms in densified delignified cellulose scaffolds

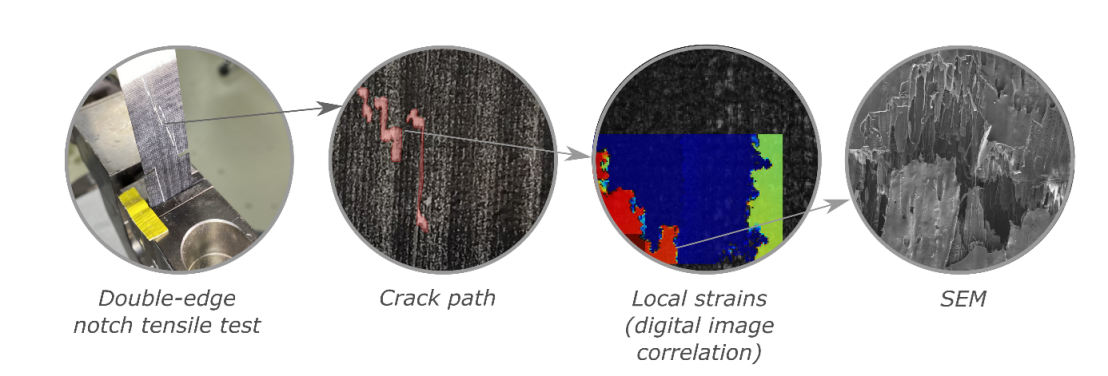

Delignification and densification treatments lead to changes in the mechanical behaviour of wood, which is verified by mechanical testing after the treatment. After comprehensive studies on the superior tensile properties of the densified delignified cellulose scaffolds, we currently focus on the basic understanding of their fracture behaviour. For this purpose, we employ basic concepts of fracture mechanics facilitated by digital image correlation techniques to characterize the toughening mechanisms of the densified delignified wood.

Enhanced mechanical properties through pure structural adjustments

One of our key activities is to develop further our concept of cellulose composites based on the delignification and densification of wood to preserve the beneficial fibre directionality. The aim of this experimental and theoretical study is to improve mechanical (fracture toughness, strength and stiffness) properties of an already existing tuneable delignified and densified wood material. We employ coupled design and dynamic FEM in order to predict progressive damage and failure in a tensile specimen. Inspired by tough natural materials (e.g. lamellar bone, palm trees and fish armour exoskeletons), we aim to devise and develop a tough inhomogeneous material by stacking and compressing of delignified wood veneer layers and gain control over the anisotropy and load-direction dependency of the mechanical properties.

Maximilian Ritter

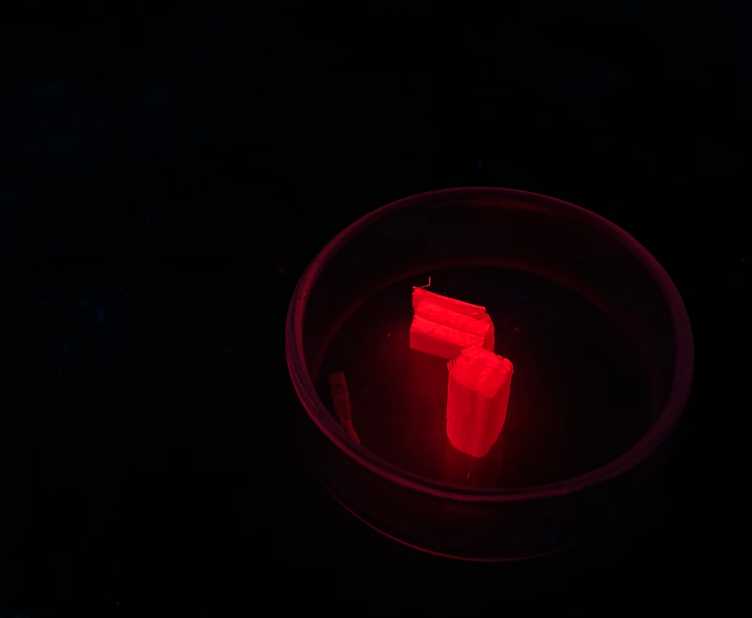

Photonic Wood

The optical properties of native wood are rather poor. Nevertheless, the study of wood-light interaction is especially promising for the development of e.g. photothermal, photochromic and opto-electronic devices. Understanding how light interacts with wood and how to inherently change this interaction to our favour is at the forefront of our research. Whilst strategies to improve the propagation of light in wood already exist, they often use fossil-based polymers resulting in non-biodegradable composites. The goal is to carefully tailor the structural properties of wood to improve the optical properties to fit our needs. Additionally, we make use of eco-friendly chemicals to introduce novel optical properties, hitherto not seen in wood.

Paul-Antoine Spies

Bio-inspired delignified and densified wood composites with high toughness and strength

Wood is an abundant natural material with excellent material properties originating from a hierarchical structure with a cellulose scaffold embedded into a matrix made up of hemicellulose and lignin. However, stiffness, strength, and toughness of natural wood don’t meet the requirements of many advanced engineering structures and applications. Stimulated by the growing demand for green, lightweight, high-performance materials, recent research efforts on wood modifications, including lignin removal treatments and densification, have achieved remarkable strength and stiffness, yet limited toughness. Paul-Antoine aims to achieve high strength, high stiffness and high toughness in delignified and densified wood composites by adapting bio-inspired toughening mechanisms.

Sandro Stucki

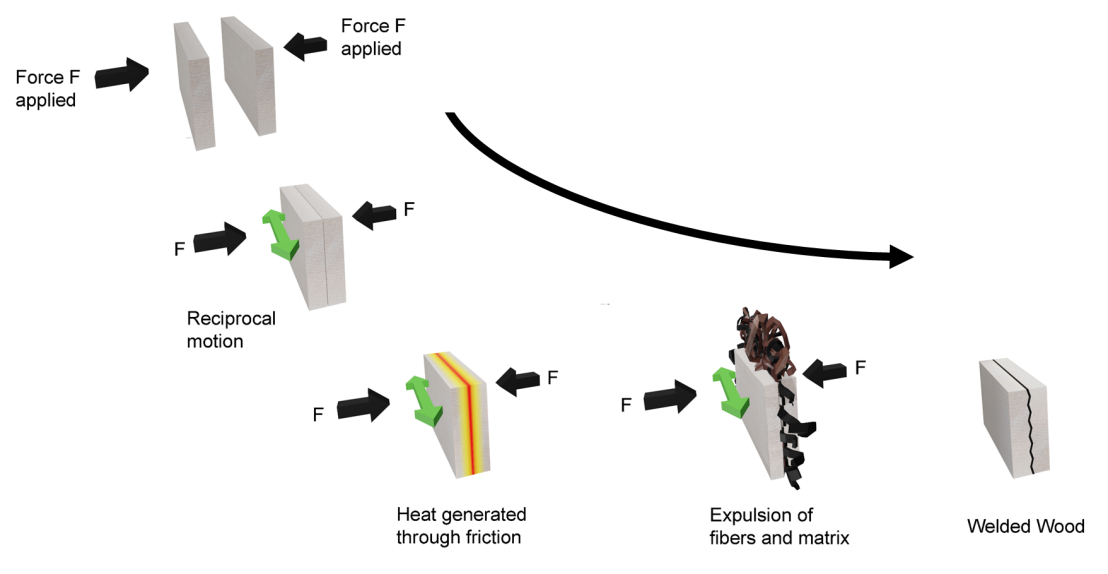

Wood Friction Welding

Linear friction welding (LFW) is a well-established solid-state joining technique for metals and thermoplastic materials. Recently, LFW has been applied to bond wood in a time and resource efficient manner. The thermal energy generated by the friction during linear movement of two timber surfaces relative to each other heats up the interfaces. This leads to a melting and fusing of the wood material across the interface, resulting in a stable bondline.

The application of welded wood is currently limited to interior applications due to the high susceptibility of the bond towards moisture changes. In this project, an improvement of the moisture stability is pursued, aiming to extend the utilization of friction-welded timber to exterior applications. This goal is approached by applying environmentally friendly interfacial primer & pre-treatments to the timber surface prior welding.

Jianguo Sun

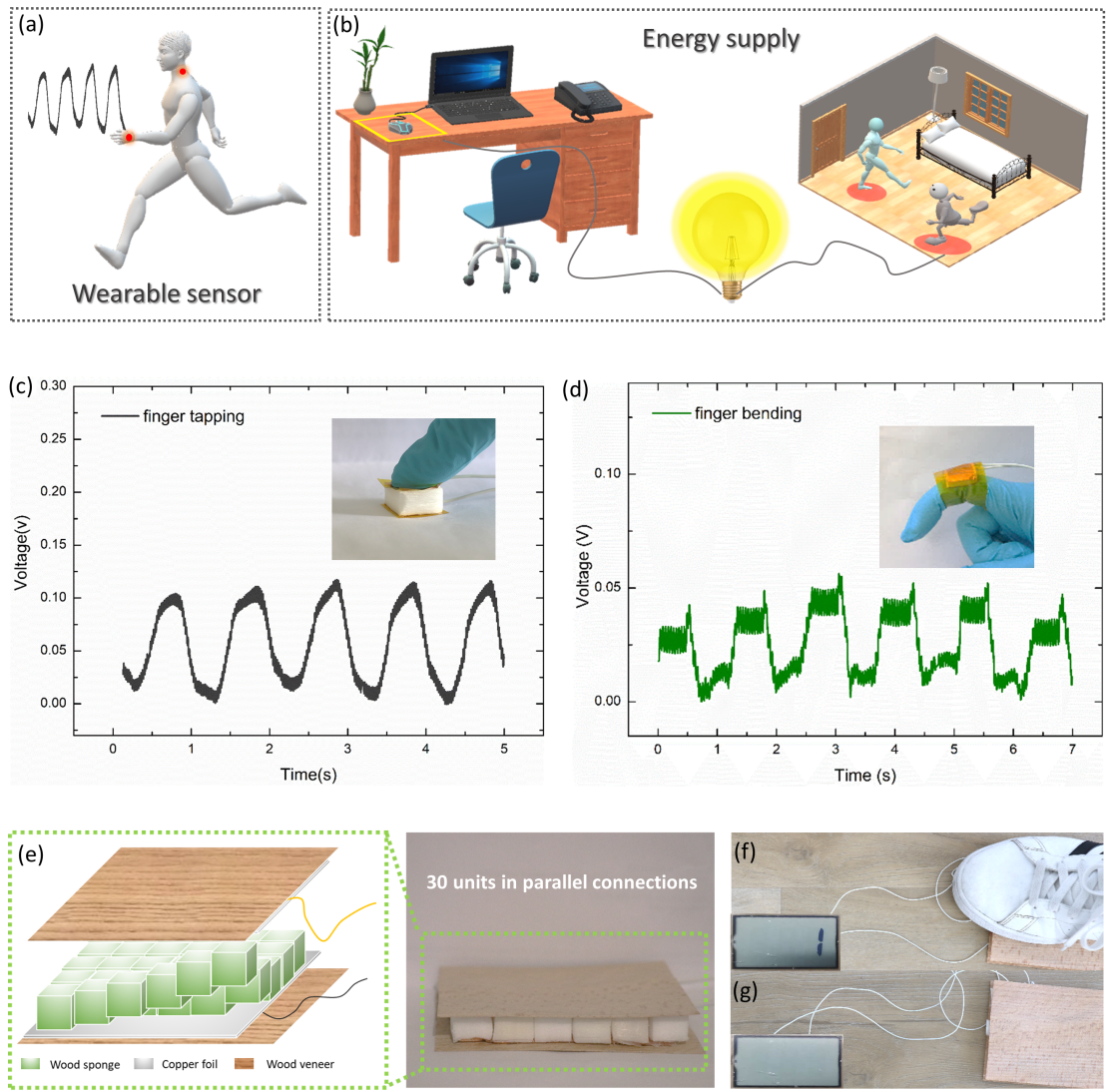

Wood Nanogenerators

Increased depletion of fossil fuels and severe environmental pollution have motivated considerable efforts to find alternative and more sustainable energy sources. Mechanical energy exists in various forms, including sound waves and human movements, which can be harvested from the surrounding environment by means of piezoelectric nanogenerators. Many materials have been utilized to fabricate piezoelectric nanogenerators, however many of these materials, such as PZT, are brittle ceramics that contain toxic elements (lead). Wood is one of the most abundant natural resources on Earth, and it is renewable, lightweight, biocompatible, and biodegradable. Thanks to the uniaxial orientation and monoclinic symmetry of crystalline cellulose fibrils, wood does behave as a piezoelectric material. However, due to the low piezoelectric constant (previously reported to be approximately 1/20 of that of quartz) and poor deformability of natural wood, limited progress has been made in the past decades for its application in piezoelectric devices. Jianguo tries to increase the piezoelectricity of wood by various methods, such as delignification, making the displacement of cellulose crystal easier under a minute load resulting in a significant increase of electrical output.

Kunkun Tu

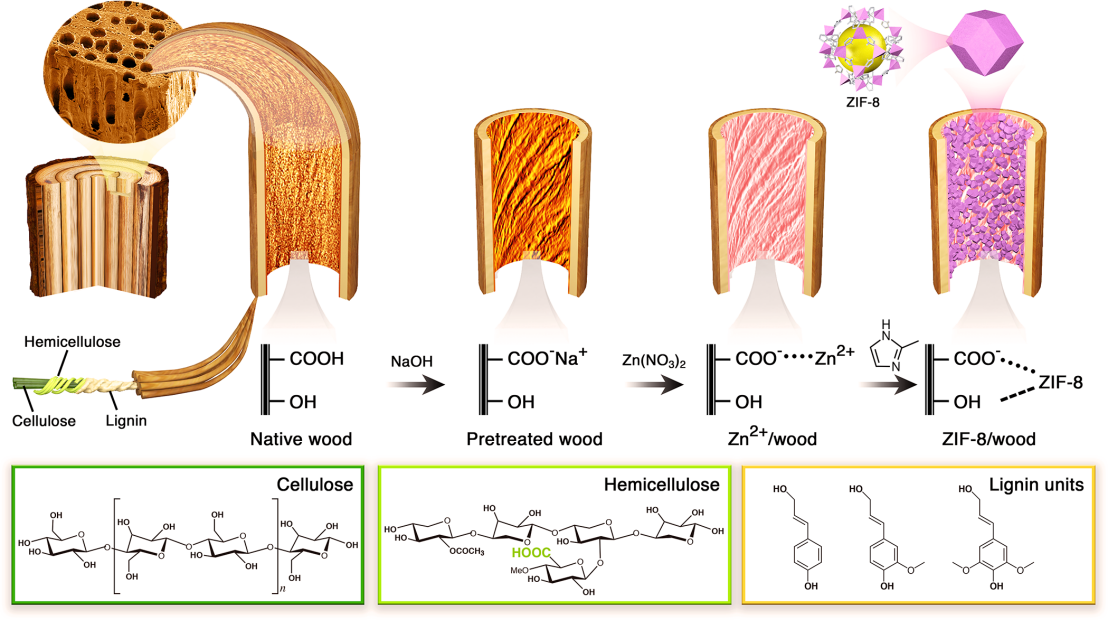

Wood-MOF Hybrid Composites

The development of novel functional materials based on sustainable and renewable resources represents one of the main current challenges in materials science. Especially wood, as one of the most abundant renewable resources, has attracted increasing attention for the development of advanced materials. Kunkun Tu’s work focuses on developing a new type of hybrid material based on the in situ formation of metal-organic frameworks (MOFs) within the wood scaffold. The hereby-obtained hybrid materials combine the intrinsic properties of wood (excellent mechanical properties of a lightweight structure) with the unique characteristics of MOFs including ultra-high surface area and porosity. This results in a new type of composite material with high potential in new applications for wood in both energy and environmental fields. In addition to the functionalization, she also conducts a detailed analysis of the wood's inherent modification pathways.

Dr. Wenqing Yan

Design of Molecularly Engineered Wood with Enhanced Durability and Resistance to Water Uptake

Wenqing`s research focuses on establishing green chemistry protocols and technologically applicable processes to enhance wood durability and water resistance for broad utilization and implementation. The functionalization methods include modification wood with hydrophobic/antimicrobial agents from renewable resources, molecular engineering by controlled radical polymerizations, in-situ mineralization, anchoring stimuli-responsive functions etc.

She is always looking forward to meeting motivated and proactive students who want to work on exciting projects (semester projects or master’s thesis).