Cellulose Composites Group

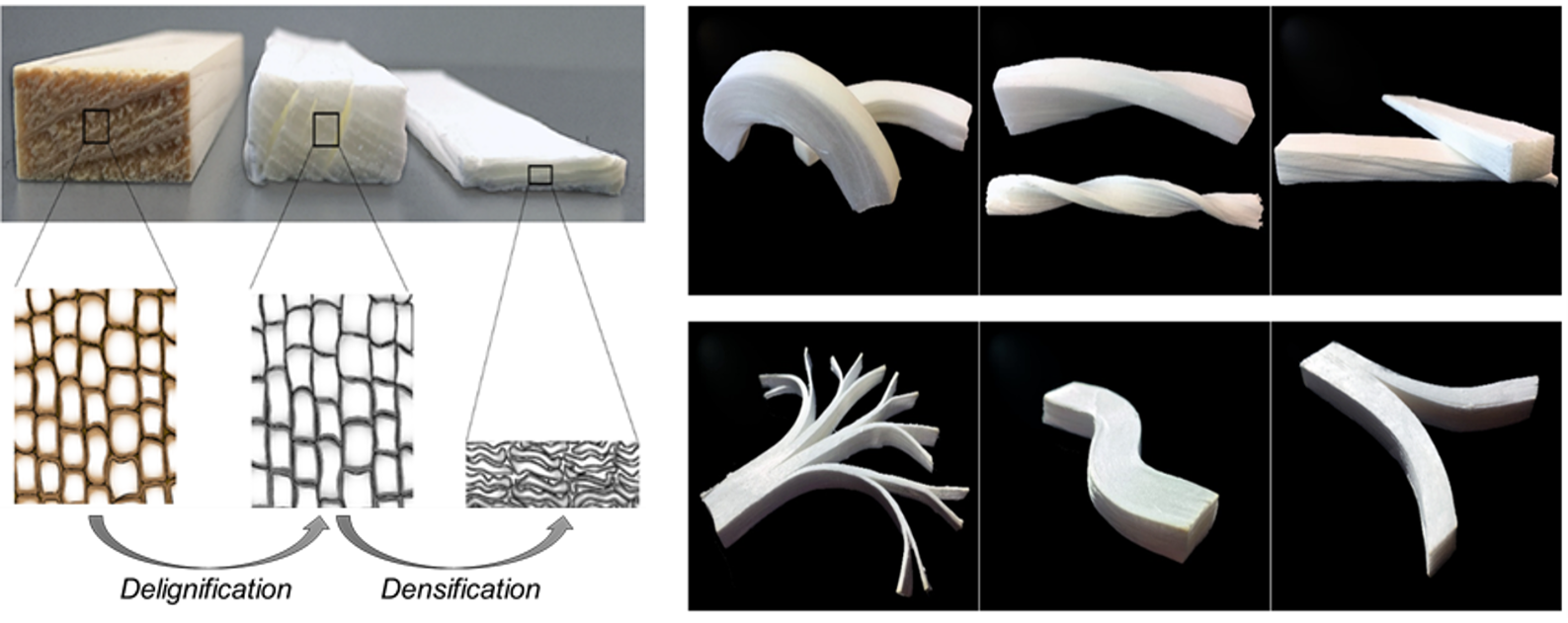

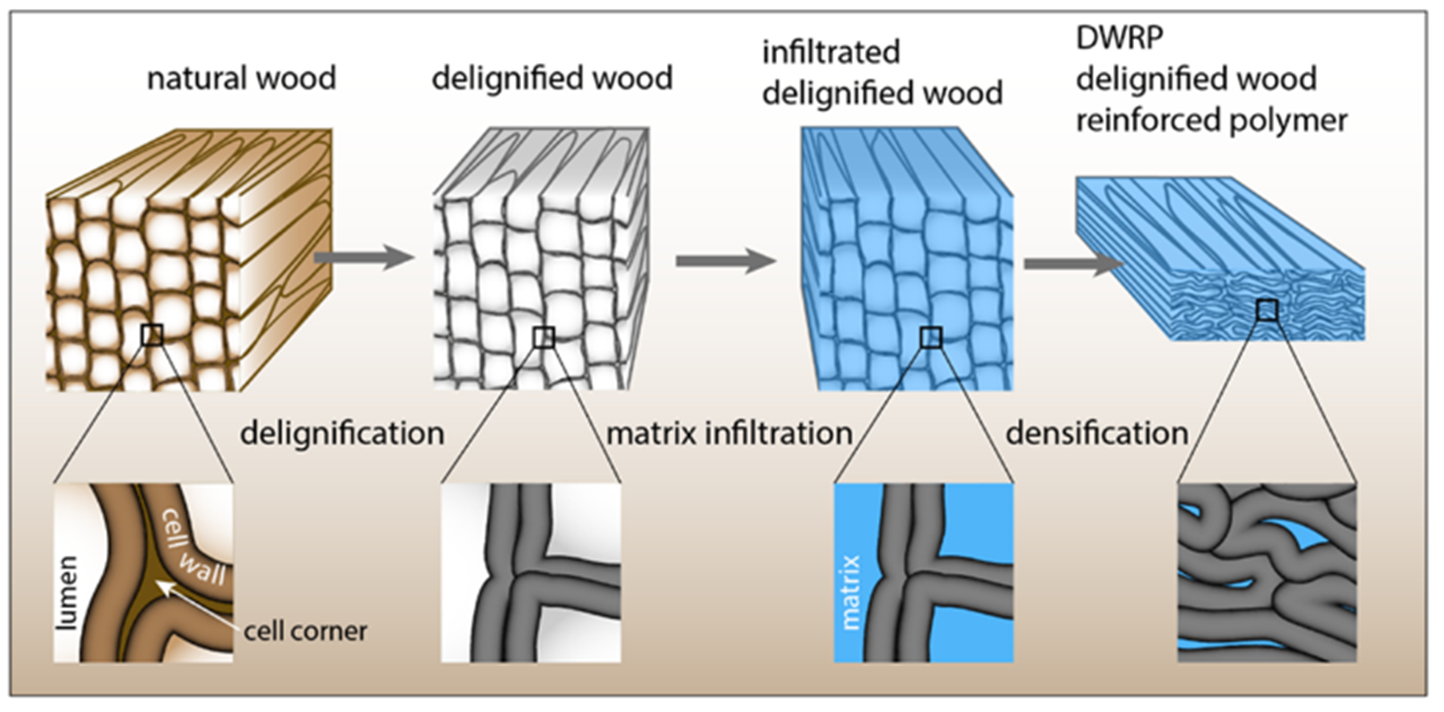

The focus of the Cellulose Composites group at the chair of Wood Materials Science is enhancing the mechanical properties of wood and introducing new functionalities by chemical modification such as delignification, i.e. to remove the matrix component lignin while retaining the inherent cellulose hierarchical architecture. The cellulose scaffolds obtained are shapeable and have high cell wall porosity at wet state, which eases functionalization and densification to high fibre volume fractions resulting in a high performance natural fibre-reinforced composite material.

Toughening mechanisms in densified delignified cellulose scaffolds

Project leader: Dr. Hajar Razi

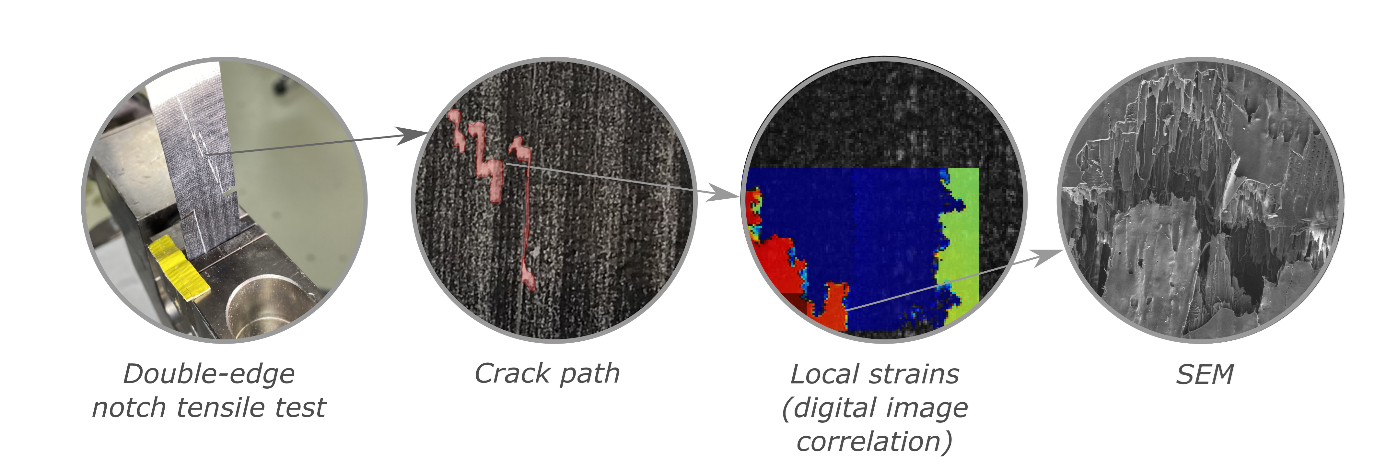

Delignification and densification treatments lead to changes in the mechanical behaviour of wood, which is verified by mechanical testing after the treatment. After comprehensive studies on the superior tensile properties of the densified delignified cellulose scaffolds, we currently focus on the basic understanding of their fracture behaviour. For this purpose, we employ basic concepts of fracture mechanics facilitated by digital image correlation techniques to characterize the toughening mechanisms of the densified delignified wood.

Enhanced mechanical properties through pure structural adjustments

Project leader: Dr. Hajar Razi, P.A. Spies

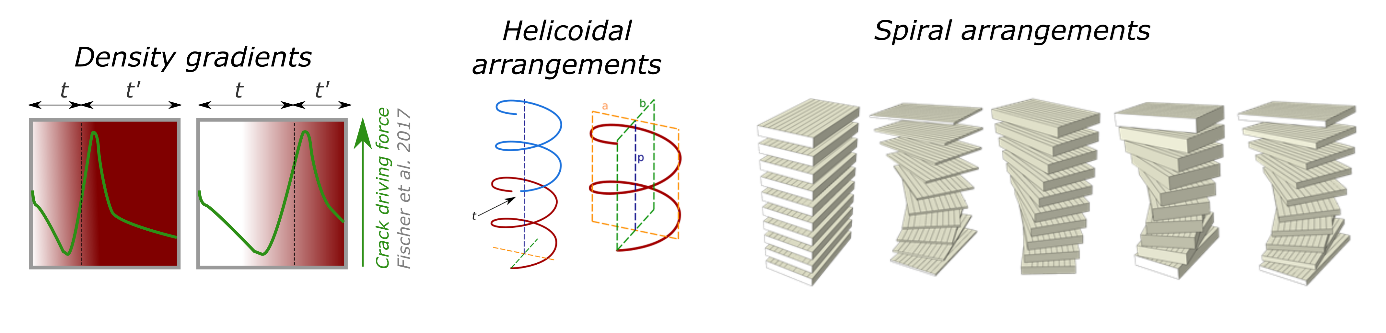

One of our key activities is to develop further our concept of cellulose composites based on the delignification and densification of wood to preserve the beneficial fibre directionality. The aim of this experimental and theoretical study is to improve mechanical (fracture toughness, strength and stiffness) properties of an already existing tuneable delignified and densified wood material. We employ coupled design and dynamic FEM in order to predict progressive damage and failure in a tensile specimen. Inspired by tough natural materials (e.g. lamellar bone, palm trees and fish armour exoskeletons), we aim to devise and develop a tough inhomogeneous material by stacking and compressing of delignified wood veneer layers and gain control over the anisotropy and load-direction dependency of the mechanical properties.

Bio-based cellulose composites

Project leader: Sophie Koch, Dr. Christian Goldhahn, Dr. Wenqing Yan

Densified cellulose scaffolds without any binder system possess excellent mechanical properties in dry state, but exposure to water or high humidity drastically diminishes the mechanical performance. For a high water resistance, which is required in almost all load-bearing applications, cellulose scaffolds need to be impregnated with a matrix system. In a first proof of concept study by former team members (M. Frey, T. Keplinger et al.), cellulose composites were produced via impregnation of epoxy resin and a subsequent densification, resulting in the required water stability and even better mechanical properties (tensile strength up to ~600 MPa, tensile stiffness up to ~70 GPa) compared to the densified cellulose scaffolds. Currently, we are testing different bio-based matrix systems on their compatability with the cellulose scaffolds and the influence of different processing parameters on microstructural features and mechanical properties. This work is embedded in an ERA-net Forestvalue project with European partners from academia and industry (see also external pageForestValuecall_made). The combination of biological and bio-based polymers with the anisotropic cellulose scaffolds yields entirely bio-based composites with great potential in various application fields.