Functional Lignocellulosic Materials - Dr. Etienne Cabane

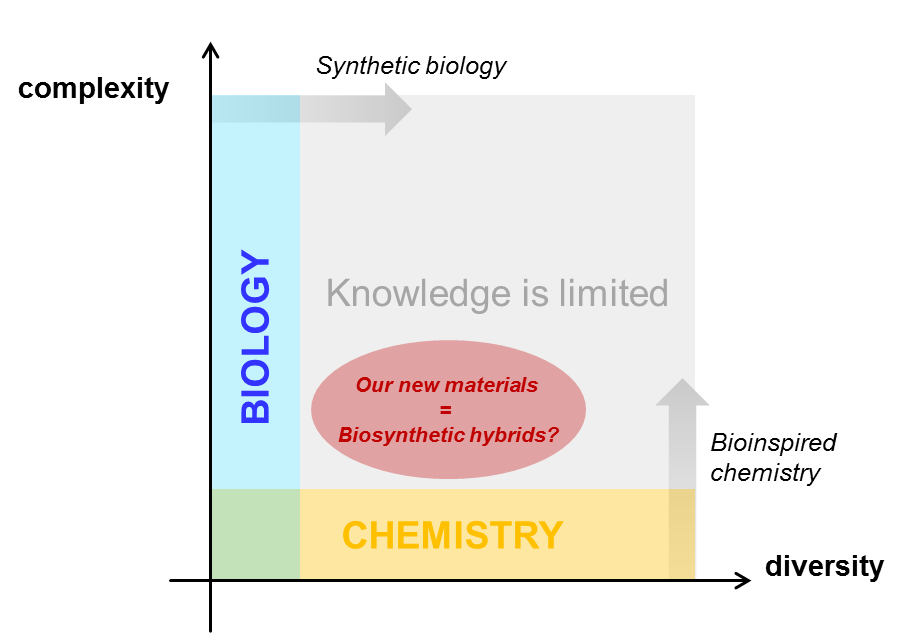

Nature is able to build structures with a limited palette of materials, but with unparalleled architectural complexity. In comparison, manmade synthetic materials are extremely diverse in nature but they are structurally more basic. These materials would have remarkably improved properties if sophisticated structures from biological materials could be reproduced in a controlled manner. Therefore, the development of new techniques to implement nano- and microscopic features into large scale structures is a major challenge facing materials scientists.

Wood is a wonderful example of a highly sophisticated hierarchical structure, which can be exploited to develop a vast variety of functional materials. As opposed to synthetic materials produced by a bottom-up approach, this hierarchical structure already provides the intrinsic solution to up-scaling problems. However, a top-down approach to material design comes with many challenges, and wood is currently limited in its applications because there is a lack of post-functionalization techniques to exploit and advance these advantageous features.

As shown in the figure below, the aim of the Functional Lignocellulosic Materials Group is to develop and utilize simple and versatile protocols for the functionalization of wood resulting in wood-based materials with novel property profiles (biosynthetic hybrids).

Wetting behavior of anisotropically functionalized wood cross-sections

PhD student: Yaru Wang

In certain applications, self-cleaning superhydrophobic surfaces can have the major disadvantage that water is lost as droplets roll away randomly from the homogeneous substrates. To prevent this, manufacturing techniques to obtain anisotropic wetting on surfaces including lithographic techniques have been developed. However, additional insight and research are still needed to optimize and scale up fabrication approaches in order to achieve low cost, mass scaling, and bio-compatibility for industrial applications. Such issues could be potentially solved with the use of a widely available natural material: wood.

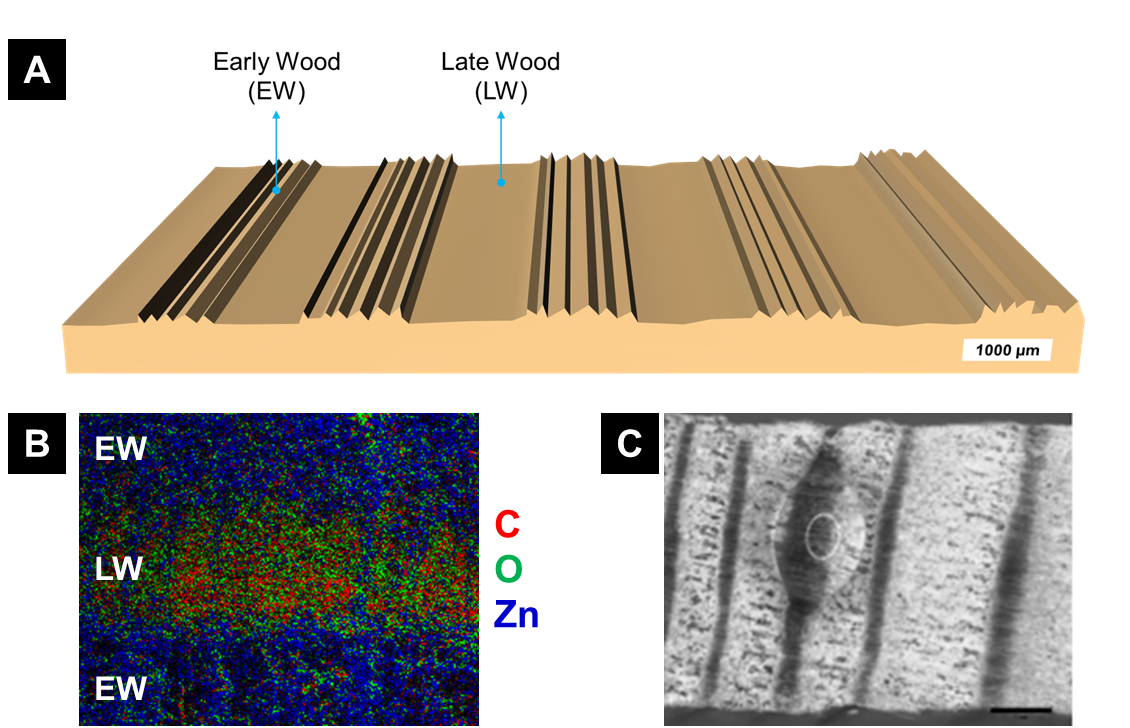

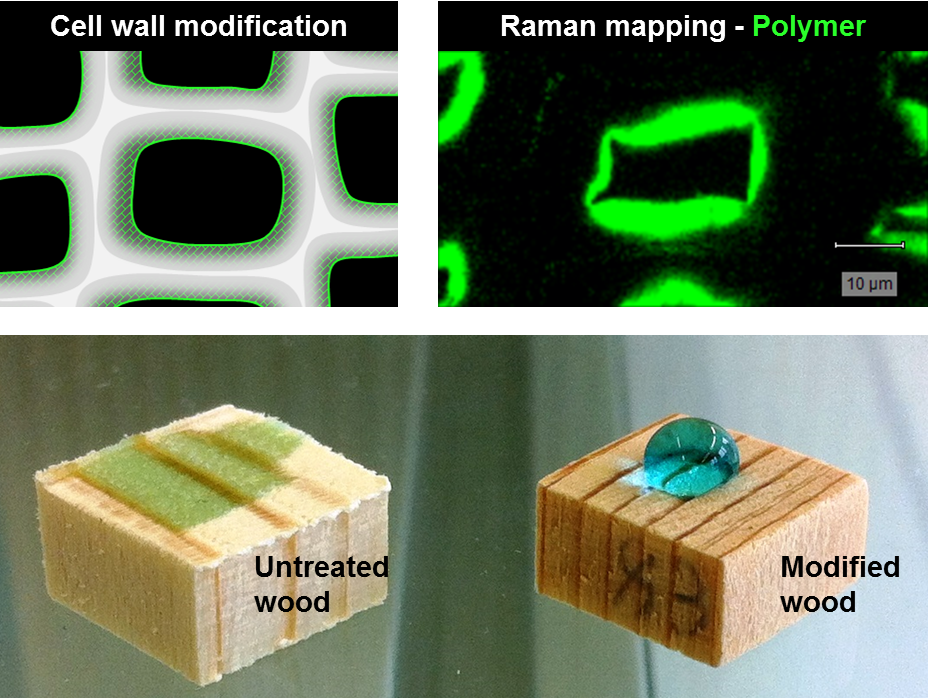

Our idea is to exploit the natural surface anisotropy of the wood substrate in terms of roughness, density, and chemistry, in order to create a surface showing anisotropic wetting. The goal of this project is therefore to develop, characterize, and understand the selective or targeted chemical modification in the wood scaffold (sol-gel chemistry and polymer grafting). In particular, we investigate the differences in impregnation and reactivity between earlywood and latewood.

No database information available

Wood-polymer hybrids with controlled hygro-responsiveness

Postdoc: Dr.Etienne Cabane

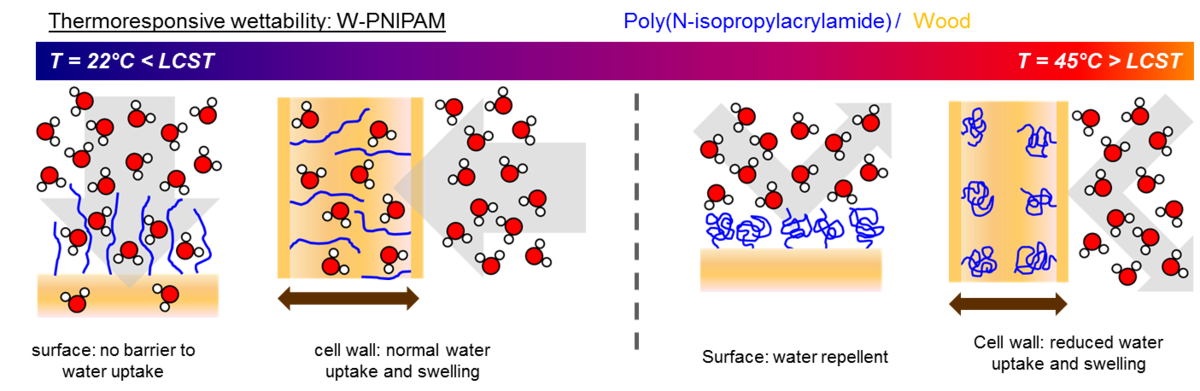

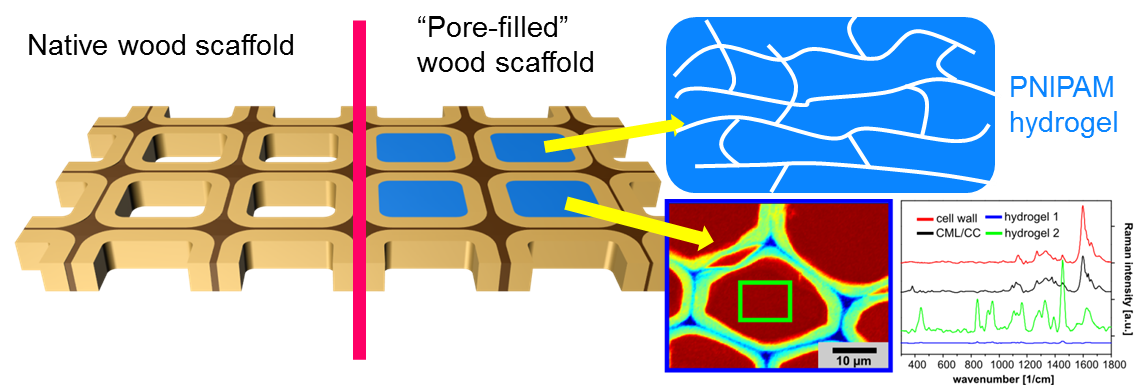

In addition to the modification of the fibers surface, the chemical transformation of the cell wall components leads to significant alterations of the wood material itself. Our goal is to partially modify wood samples while preserving the wood structure, via the introduction of responsive polymers within the cell wall voids. According to polymers nature, the wood-polymer hybrid material can be made responsive to selected external triggers. As an example, we have been working on the introduction of temperature responsive polymers (PNIPAM) within the wood structure. The concept is described in the scheme below.

Preliminary results indicate that the wood-polymer hybrid material obtained has very different properties after modification, especially in terms of water uptake in response to temperature.

No database information available

Former Projects

Wood filter technology for waste water treatment

PhD student: Selin Vitas

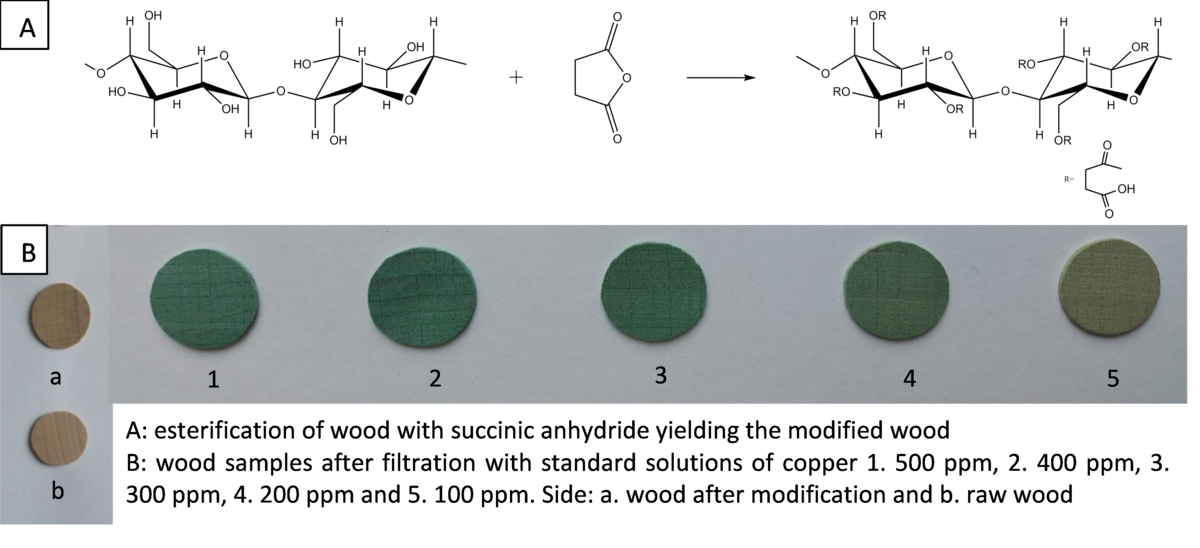

The removal of heavy metals is still a crucial step in the treatment of waste water. Actual strategies often imply the use of chemical coagulants, salts of aluminium or iron that bind the heavy metal to form a floc. The flocculation has to be combined with a filtration step and the filtrate will undergo further treatments before entering the water supply. The scope of this project is to develop a filter able to strip the heavy metal directly from a contaminated flow.

Wood is a readily available natural material with anisotropic porosity. Its natural ability to transport water throughout its hierarchical structure makes it a material of choice for the development of innovative filters based on renewable resources. Some hardwoods, such as beech (Fagus sylvatica) may be of particular interest in this case, due to the presence of long and relatively large vessel structures.

However, wood cell wall components (cellulose, lignin, and hemicelluloses) mainly offer hydroxyl groups as reactive or binding sites. In order to improve the affinity of the filter towards heavy metals, we develop various chemistry approaches to increase the content of functional groups (carboxylic acids and amines) able to capture heavy metals (see an example in the figure below).

We believe that the tuneable properties of wood allow for its use in the field of water treatment and to provide cheap and robust alternatives to actual systems.

No database information available

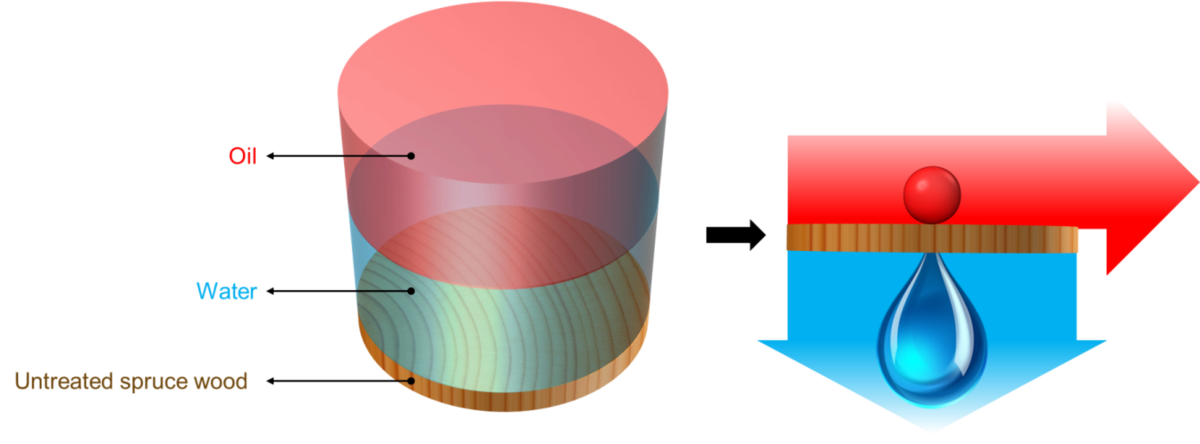

“Wood membranes” for oil-water separation

PhD student: Marta Vidiella del Blanco

Over the last years, the awareness over oil spill accidents in marine environment and aquatic ecosystems has increased leading to tighter regulations. Novel strategies to separate oil-water mixtures from industrial wastewaters, polluted oceanic and river waters have become a global challenge. Given that traditional methods are limited with regard to their energy costs, low efficiency and complexity of the separation, new functional materials, which fulfil these restrictions are highly needed. We are currently working with wood to develop filters able to separate oil from water. The hierarchical porous structure of wood recalls the structure of the widely used separation membranes manufactured with conventional polymers. Spruce (Picea abies) is the perfect material for this application. By the combination of the natural structure of wood, the surface roughness generated by the cutting process, and a clever combination of interfacial energies obtained through chemical wood modification, we can develop a material with interesting wettability properties that is capable of separating oil from water.

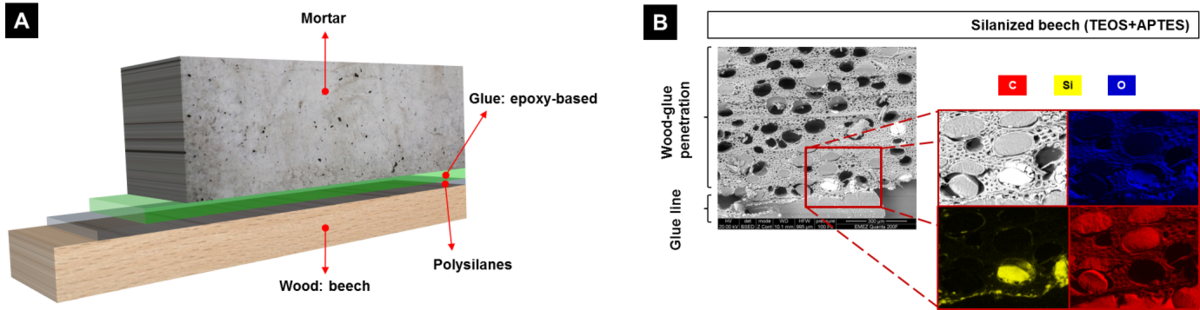

Wood surface modification for improved compatibility with concrete

PhD student: Sanja Kostic

Wood-concrete structures are gaining importance in the construction industry. As opposed to traditional building materials, wood represents a more sustainable solution, and has great advantages, such as its lightweight. Up to date, connections between timber and concrete have been achieved through mechanical fastenings such as screws and bolts, while adhesive connections were largely overlooked. The main benefits of glued wood-concrete structures are to obtain an equal distribution of force concentration and a more rigid interface, and its main drawback is the challenge associated to low compatibility in between wood and concrete. Our goal is therefore to modify the wood surface in order to promote adhesion at the interface wood-concrete.

An elegant method to promote adhesion between dissimilar materials is the use of organofunctional silanes (alkoxysilanes). Upon hydrolysis, alkoxysilanes can undergo a condensation reaction with the free hydroxyl groups at the surface, hence forming a sol-gel surface modification. In this project we intend to use alkoxysilanes with amino functionalities: this approach will provide novel functionalities and act as a priming system which may enhance crosslinking between amino functionality and epoxy glue, guaranteeing an improved adhesion system between wood and concrete.

Modified wood for the development of new engineering materials

Postdoc: Dr. Tobias Keplinger

Surface-initiated polymerization techniques are a powerful tool for the functionalization of various surfaces. In its native state, wood mainly offers –OH groups that we have used for ring opening polymerization of cyclic esters. Pretreatment of wood with various precursors, such as polymerization initiators or alkene bonds, offers numerous possibilities for wood functionalization. Depending on the polymer nature and grafting location within the wood structure, new materials with many different profiles can be synthesized. In a recent work, we have developed novel wood-hydrogel composite structures, with the implementation of a PNIPAM thermo-responsive gel within the luminal area in a spruce wood cross-section. Bio-inspired Wood Materials group

No database information available

Hydrophobized wood for more sustainable wood-based materials

Postdocs: Dr. Etienne Cabane, Dr. Mahmut Ermeydan & Dr. Tobias Keplinger

In this project, the chemical modification of wood aimed at wood hydrophobization. In particular, due to its hygroscopic nature, wood absorbs and desorbs water upon humidity changes, which makes it swell and shrink and hence dimensionally unstable. We followed two approaches: small molecules can penetrate the hygroscopic wood cell walls easily and can be used to establish covalent bonds addressing functional hydroxyl groups of the natural polymers (lignin, cellulose, and hemicellulose). Another approach consists in bulking the micro- and nano-voids in the cell walls with reagents that can be locked in wood and provide permanent dimensional stability and water repellence.