Wood Actuation & Mechanics - Dr. Markus Rüggeberg

The group is interested in two aspects of wood.

We analyse cell wall and tissue mechanics down to the molecular level using native, genetically and chemically modified wood. On the other hand we use the swelling and shrinking of wood for developing smart materials which are capable of reversible actuation on large scale in response to changes in humidity.

Wood mechanics

The mechanical behaviour of wood is largely influenced by the structure and biochemistry of the cell wall. By mechanical testing and correspondingly analysing native, genetically and chemically modified wood we aim at elucidating structure property relationships of the wood cell wall. Hereby, we cover the different hierarchical levels in mechanical testing and analysing structure and biochemistry.

On macroscopic scale testing is being done with universal mechanical testing machines (LINK TO EQUIPMENT) and with a custom-built microtensile testing machine (LINK). On microscopic scale we use in-situ micropillar compression tests (Collaboration with EMPA Thun) and on nanoscale force mapping with the AFM (LINK).

Structure and biochemical analysis is done by EM, X-ray diffraction, Raman and FTIR-Analysis.

Mechanical properties of chemically modified wood

PhD student: Samuel Olaniran

One focus of the chair Wood Materials Science is the enhancing of the properties of wood and the introduction of new functionalities by chemical modification. Part of these treatments also lead to changes in mechanical behavior of wood, which is to be verified by mechanical testing after the treatment. However, in some cases, the treatment of chemical modification is quite harsh which bears the danger of losing stiffness, strength and toughness of the wood. Thus, mechanical testing of chemically modified wood is an integral part of the process of enhancing and functionalizing wood.

Wood actuation

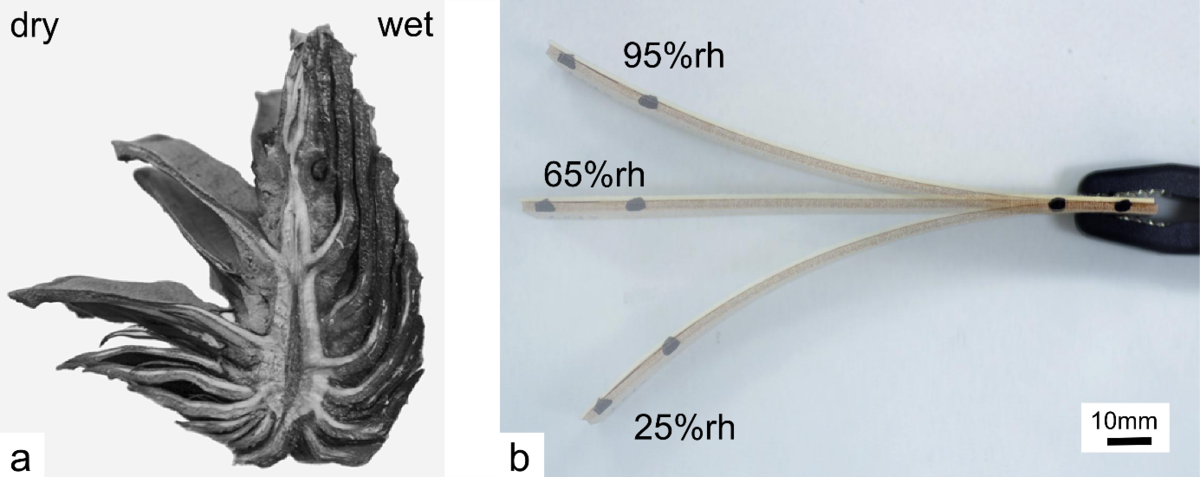

The swelling and shrinking of wood is commonly seen as disadvantage in the use of wood as construction material. We perceive this inherent property of wood as a genuine capacity, which can thus serve as a highly valuable material for the generation of smart responsive structures. Inspired by the responsive behaviour of different plant organs such as the opening and closing of pine cones, we analyse the principle behaviour of wooden bilayers for its use in responsive elements in architecture and construction.

Plant tissues take up and loose water when exposed to fluctuating relative humidity. This hygroscopic nature comes along with dimensional changes. Nature makes use from these properties and has developed plant organs which are actuated in response to changes in relative humidity. Pine cones, wheat awns and orchid tree seedpods generate complex and reversible movements following changes in relative humidity for effective seed dispersal (Dawson, Vincent et al. 1997, Elbaum, Zaltzman et al. 2007, Erb, Sander et al. 2013). In many cases, the actuation is achieved by bi-layered tissue structures with specific fibre orientations in the individual layers. The differential fibre orientation leads to a transformation of the dimensional changes to reversible bending and twisting movements

In our research, we explore Nature’s materials and design principles which allow such autonomous water-actuated movement. In this respect, wood is unique as it inherits responsiveness to function as a smart material and excellent mechanical properties and a good workability to function as an engineering and building material for creating large scale components. By taking wood and understanding the underlying design principles, we are able to develop biomimetic convertible elements that move as a result of daily changes in air humidity or rain exposure without needing additional engines or control.

Wood actuation

PhD student: Grönquist Philippe

The anisotropic material wood can produce large deformations under moisture content changes when assembled as a bilayer structure, because of its capacity to swell and shrink in the hygroscopic range. The two layers are usually glued in a cross-ply manner, where the resulting deformation (bending, twisting, and mixed-modes, depending on angle between the grains of the two layers) is seen as function of geometry, material characteristics and wood species, and applied moisture content change. We investigate the applicability of this principle for innovative large-scale wooden elements for utilization in architecture and construction industry. We further aim at quantifying the predictability of the deformation using analytical models and Finite-Element numerical models to reflect the complex moisture and time dependent mechanical behavior of wood.

No database information available