Laboratory equipment

List of equipment of the corrosion and electrochemistry laboratory

Electrochemical workstations

Four full-featured potentiostats/galvanostats, capable of performing all techniques, including electrochemical impedance spectroscopy:

- Metrohm Autolab external pagePGSTAT30call_made with Nova 2.1

- Metrohm Autolab external pagePGSTAT302Ncall_made with Nova 2.1

- Gamry Interface external page1010Ecall_made (x5)

Dataloggers for corrosion monitoring

In total, we have capacity to continuously log 120 channels of potentials and currents. We use the following instruments:

- external pageKeithleycall_made 2701 + Multiplexer 7702

Benchtop and handheld multimeters

- Keithley external page2000call_made

- Keithley external page2001call_made

- Escort LCR meter

- Gossen Metrawatt «Geohm»

- Various handheld multimeters (Fluke, etc.)

Laboratory instruments

- Mettler Toledo external pagepH- and Conductivity-Metercall_made

- Sutter Instrument external pageModel P-97 Flaming/BrownTM Type Micropipette Pullercall_made

- Rotating Disk Electrode (IPS)

- Thorlab Active Light Reflectance Spectrometer UV-Vis

Non-destructive test equipment

- Proceq Canin+ (for on-site measurements of electrochemical potentials with a single or a wheel electrode in order to detect corrosion in a concrete structure).

- Proceq external pageProfometer 650 AIcall_made (for on-site measurements of concrete cover and/or rebar dimensions).

- Proceq external pageGPR Livecall_made – Ground Penetrating Radar (for on-site detection of rebars, delaminations, etc. in reinforced concrete at depths up to 70 cm)

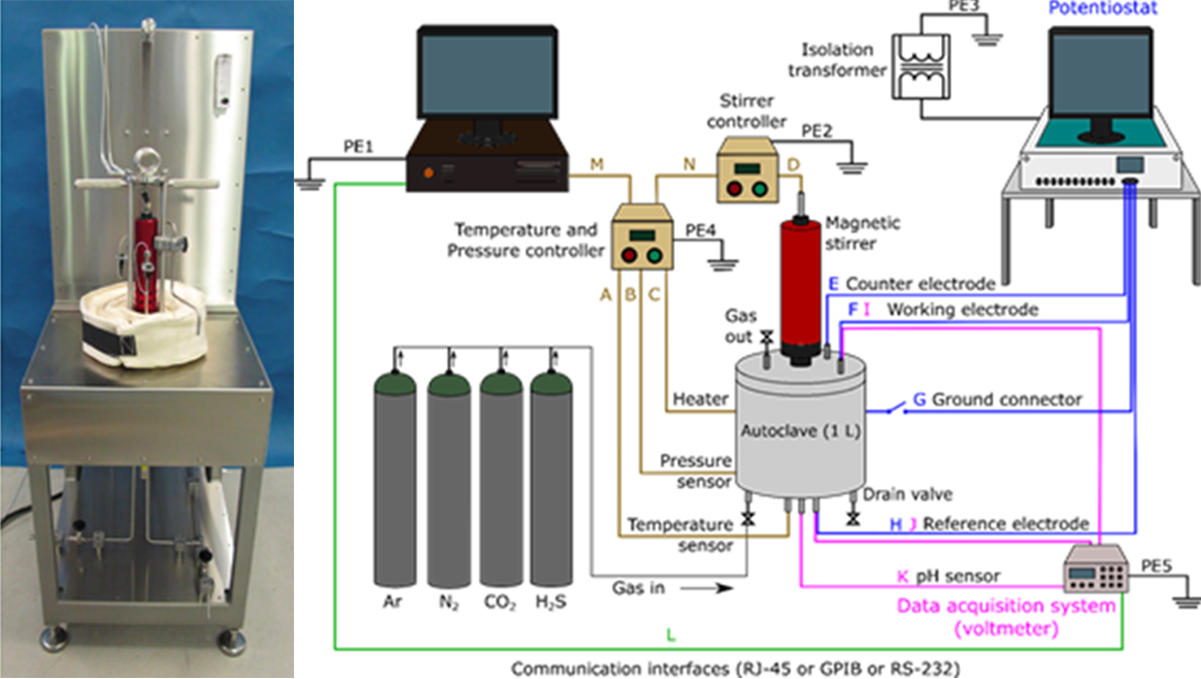

Setup for electrochemical corrosion testing at elevated temperature and pressure

We have a high temperature (up to 220 °C) and high pressure (up to 70 bar) electrochemical autoclave (1-L volume), equipped with a external pagemagnetic stirrercall_made, a external pagepH sensorcall_made, and gas needle valves to inject different gases (N2, Ar, CO2, H2S). The autoclave setup also contains a reference electrode (Ag/AgCl/sat. KCl) and a counter electrode and allows for complete online electrochemical testing.

We used this setup primarily for corrosion studies in the context of deep geothermal energy installations.

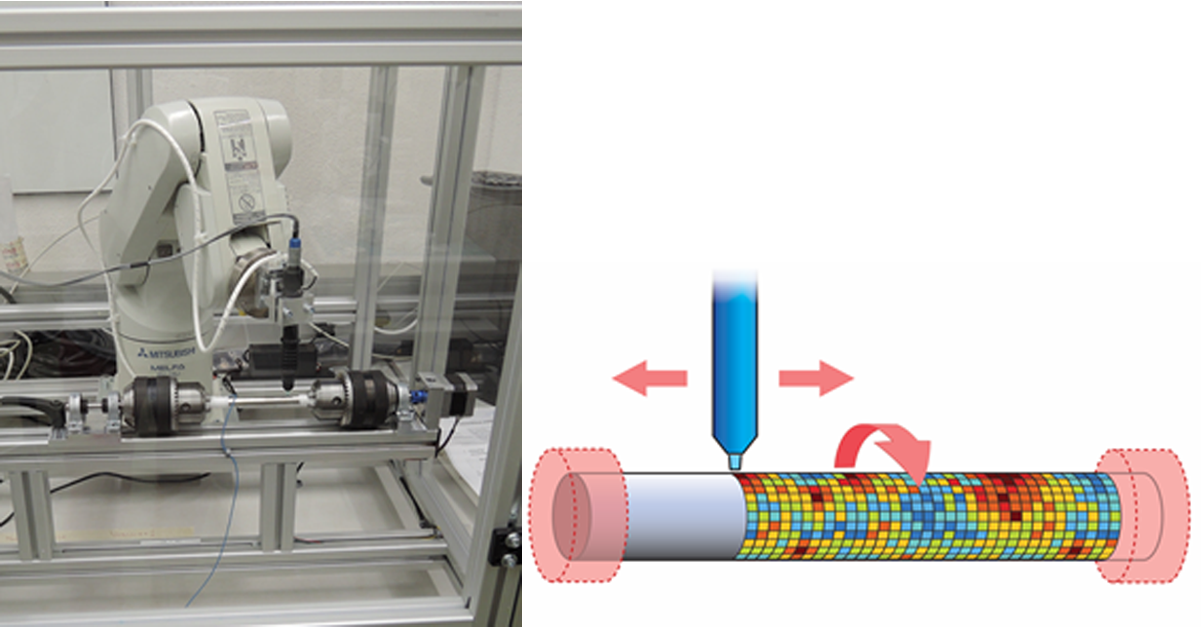

Automated local electrochemical metal surface characterization

We have a self-developed robotic system that allows positioning a local electrochemical probe on pre-defined locations on metal surfaces. A particular advantage is that this can be applied to non-flat metal surfaces, including corrugated reinforcing steel bars, where the entire circumference of the bar surface can be electrochemically characterized. The setup consists of a 5-axes robotic arm, used to position a local electrochemical sensor. This sensor consists of a reference electrode and a counter electrode and an electrolyte compartment as well as a porous membrane tip (contacting area approx. 1 mm2) to locally bring the electrolyte into contact with the metallic specimen under test. The robotic setup has an interface to communicate with a potentiostat (Gamry Interface 1010) to fully automate the electrochemical mapping of the metal sample.

More detailed information about the local electrochemical characterization technique can be found in the following publication:

Linux node for numerical simulations

For more demanding computations there is a linux server which can be used by our group. It contains a 16 core AMD CPU, 128 GB RAM, and a nVidia RTX 3090 GPU.